Kodachrome and Dynachrome films, unlike virtually all other color films, had the color dyes added to the film during the processing and not built into the film, as all currently produced color films do. When the Kodachrome patent ran out in the late 1950s, 3M copied the Kodachrome film and released “Dynachrome” which has most of the same characteristics and properties of Kodachrome – including it being difficult to scan well. Some department store slide film brands such as “Sears” were actually repackaged Dynachrome film. You can usually tell what you have by the fact the color has stood up fairly well. Also, if you glint light off the emulsion side (dull side) of the film, there’s a sort of bas-relief effect to the surface of the film. Almost like the image is engraved onto the base of the film.

Kodachrome Issue 1 – Infrared dust and scratch removal systems don’t work properly

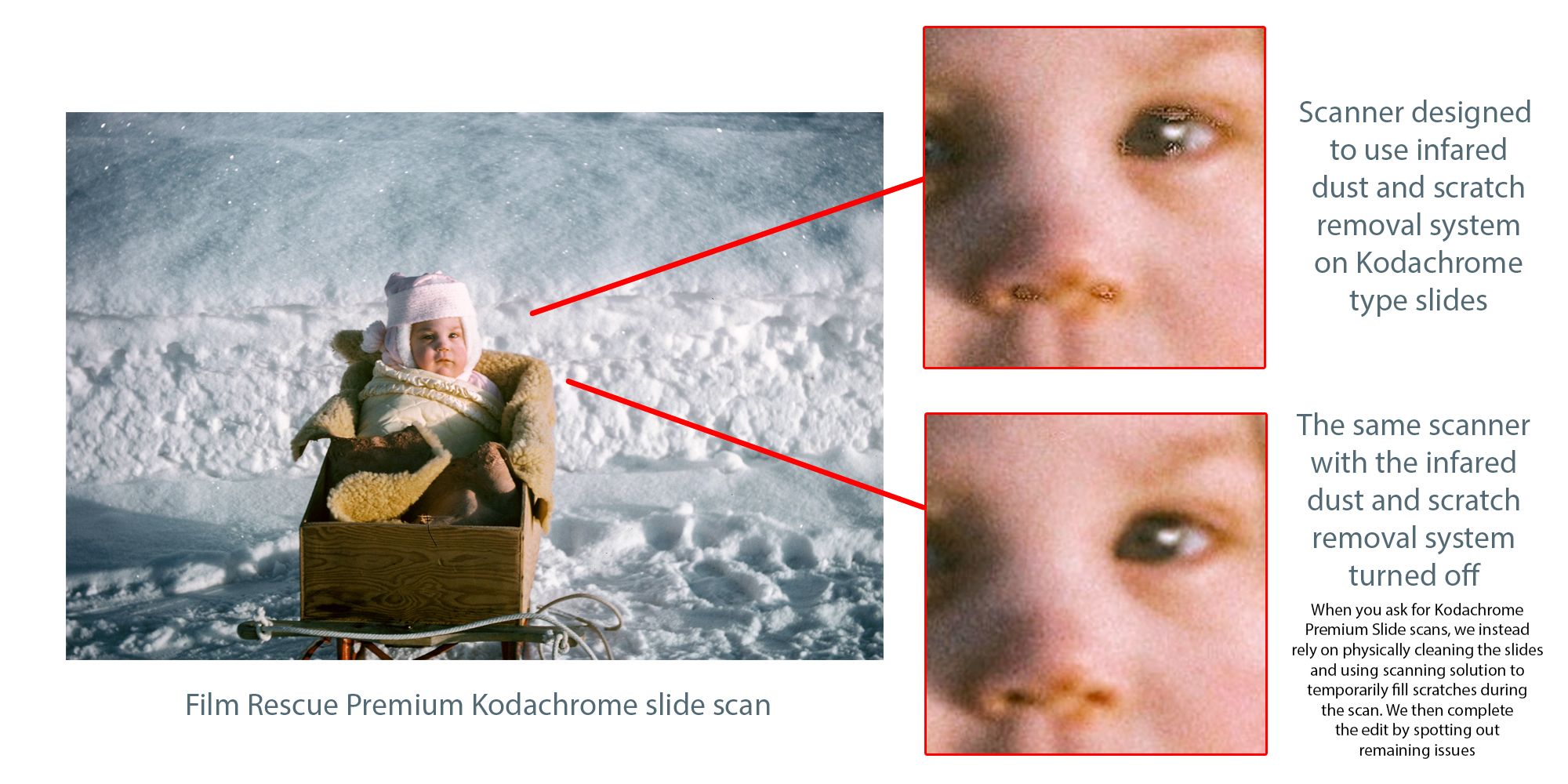

Also unique to this film is that after developing, there were some metallic silver compounds left behind in the emulsion. These silver compounds confuse the IR dust and scratch removal systems in modern scanners. To get a scan without artifacting, these systems must be left turned off. Even though our Fuji SP-3000 scanners are designed to scan these films with the IR system on, it’s not perfect and on close inspection you will some imperfections. See image below.

While Kodachromes had great image permanence as far as color films available at the time went, they weren’t perfect and at this point most of the pre 1970s Kodachromes do have some degree of fading. In our Photoshop edit, we’re doing what we can to restore life and vibrancy to your Kodachrome or Kodachrome type slides. In our edit we’re adjusting…

- Highlight color

- Midtone color

- Shadow color

- Highlight detail

- Shadow detail

- Contrast

- Removing remaining dust and scratches

More often than not, we’re making a significant difference in quality compared to the original slide. We can’t always make them perfect but we can almost always improve them.

Kodachrome Issue 2 – Lacquer damage

Up until sometime in the early 1970s, there was a protective lacquer applied to Kodachrome film. It was to protect against minor scuffing, fingerprints and mold…which it may have well done for some time. It is now likely yellowing, possibly capturing contaminates between the emulsion and the lacquer and ironically, susceptible to mold. If the lacquer on your film is in good shape, it’s probably okay to leave it there but by removing the lacquer, we are often also removing the beginnings of mold and trapped dirt and grime even if not immediately apparent upon inspection.

With extra time and attention, we can do an impressive scan of these films. If the difference between having the IR dust and scratch removal system turned on or off isn’t worth the extra expense, and/or your film isn’t suffering lacquer deterioration, you can opt to have your Kodachromes scanned at our lower price (that doesn’t include your slides being physically cleaned and coated in scanning fluid before scanning).